Paris is undeniably the world’s sporting epicentre this summer, with Olympic events across the city. Amidst this global spectacle, Japanese sports giant Asics has made its mark by opening the Asics House in the 16th arrondissement. The company, boasting €3.4 billion in annual sales, has created a hub for athletes and partners to converge.

Furthermore, it was also an opportunity to showcase a range of initiatives, including the high-altitude Chojo Camp, the eco-friendly Nimbus Mirai shoe, and the groundbreaking Asics Personalisation Studio, which offers athletes custom-made insoles in just a few hours.

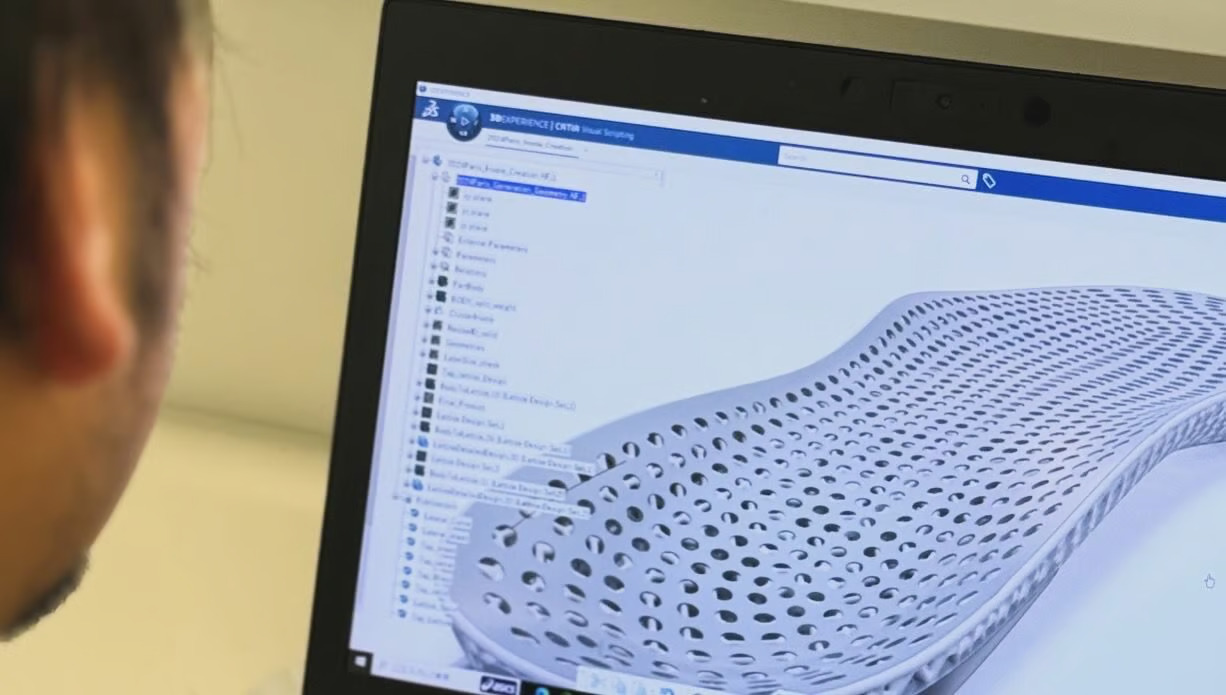

In addition, Asics has teamed up with Dassault Systèmes, based near Paris, to revolutionise insole customisation. Building on the brand’s experience in gait analysis using in-store treadmills, the partnership has developed a modular system for producing personalised insoles through 3D printing.

These custom insoles are designed to be produced within an hour and tailored to individual athletes’ biomechanics and performance requirements. Next, while currently undergoing testing with elite athletes, the technology promises to deliver unmatched comfort and performance for runners of all levels.

“We’ve successfully demonstrated the viability of this concept, and it’s clear that athletes have a strong demand for personalised solutions,” said Benoît Dauchin of Dassault Systèmes. “You can customise individual insoles for performance enhancement, injury prevention, or specific running conditions.” Our approach involves creating a virtual twin of the athlete’s foot, which allows us to optimise the insole’s design beyond simply matching the foot’s shape. This digital model enables us to tailor the insole precisely to the runner’s unique needs.”

Additionally, the collaboration between Asics and Dassault Systèmes holds significant potential for the industry. The current studio, capable of producing fifty custom insoles per hour, is just the beginning. Its compact design allows for flexible deployment, bringing personalised production closer to consumers. Furthermore, Asics teams in Japan will test the technology before eventually releasing it to the general public.

“We are thrilled to partner with Dassault Systèmes on the Asics Personalisation Studio,” said Mitsuyuki Tominaga, President and COO of Asics. “By combining our expertise with Dassault Systèmes’ advanced technology, we’re creating a new standard for personalised products that enhance the lives of our customers.”

Next, integrating data collected by the brand and technologies, particularly those from Dassault Systèmes, opens up many new possibilities. “With a digital twin, we can test various scenarios. What’s even more intriguing is compiling these elements over time and leveraging generative artificial intelligence.

By connecting this with brand identity and CRM aspects, we can craft highly targeted offers for riders. Furthermore, transitioning from real-world data to simulations and back again allows us to significantly reduce development times and base our product creation on more scientific data.”

Data collection remains central to this process. This often involves sharing sensitive information like health history, training data, and gait patterns to optimise product performance in sports.

Additionally, while providing athletes with tailored solutions is the primary goal, this new era of customisation offers exciting opportunities for future innovation.

“By training a model that encompasses all facets of our business, from supply chain to brand heritage, marketing, and production, and combining this with detailed customer data, we can generate highly tailored solutions that perfectly align with consumer expectations and needs,” explained Benoît Dauchin enthusiastically.

This development promises optimal comfort and support for post-performance recovery and injury rehabilitation. Advanced technology and generative AI combined will revolutionize wellness and healthcare offerings.